- International

- Argentina

- Australia

- Austria

- Belgium

- Brazil

- Canada

- China

- Czaech Republic

- Denmark

- Finland

- France

- Germany

- Hong Kong

- Hungary

- India

- Ireland

- Italy

- Japan

- Mexico

- Netherlands

- Norway

- Philippines

- Poland

- Portugal

- Republic of Korea

- Romania

- Russian Federation

- Singapore

- Slovenia

- South Africa

- Spain

- Sweden

- Thailand

- Turkey

- UAE

- United Kingdom

- United States

FlexTack

The Flexible Mount for Attaching Bundles on Curved Surfaces

Customers regularly share installation challenges with us, which leads to many of the innovative solutions developed here at HellermannTyton. That’s how the first wire-management-specific flexible adhesive mount came to be.

FlexTack Adhesive Cable Tie Mounts deliver excellent mounting performance on curved and moderately angled surfaces – for example, along curved conveyor frames, ductwork, tubular machine frames and rails and more.

FlexTack Adhesive Cable Tie Mounts deliver excellent mounting performance on curved and moderately angled surfaces – for example, along curved conveyor frames, ductwork, tubular machine frames and rails and more.

Once the mount is placed in position, cable ties can be inserted in any of four directions to secure bundles as needed.

Great Grip – Without Drilling

Often, drilling a mounting hole is not possible – or it’s simply undesirable. FlexTack utilizes a high-strength acrylic adhesive that delivers excellent performance in most environmental conditions for a wide range of indoor and outdoor applications.

FlexTack is designed for use on varnished, powder coated, bare metal or plastic surfaces as found in most electrical and industrial applications. Two colors are available to complement aesthetics.

Use the FlexTack mount in combination with 18- through 50-pound cable ties to provide reliable stability when securing bundles.

Features and Benefits

One base fits more surfaces – flat, curved and moderately angled – for versatile applications.

High-strength, weather-resistant adhesive offers excellent performance indoors and out.

4-way opening allows parallel or perpendicular cable routing options.

The World is Not Flat

FlexTack was developed because our world is filled with curved and moderately angled surfaces that would make ideal places to route and mount wire, cable and hoses.

Prior to FlexTack, product designers and MRO technicians were sometimes relegated to find workarounds to manage bundles running along non-standard surfaces.

Prior to FlexTack, product designers and MRO technicians were sometimes relegated to find workarounds to manage bundles running along non-standard surfaces.

The flexibility of this mount means greater flexibility in bundle management. Imagine the possibilities for your unique applications. Then, contact us for samples, or visit your distributor.

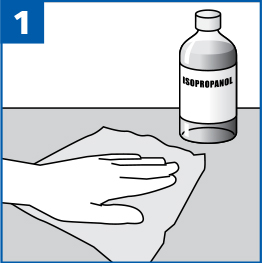

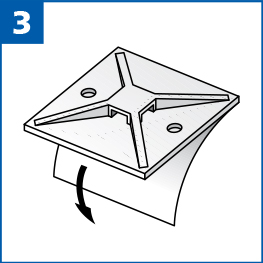

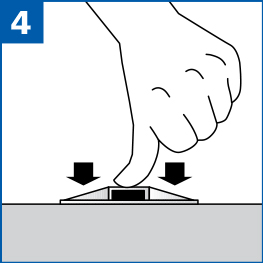

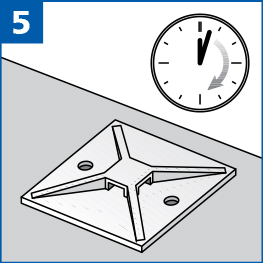

FlexTack Instructions

1. Mounting surface must be thoroughly cleaned prior to applying adhesive pad. Use a 50/50 mix of isopropanol and water for best results, as commercial cleaners may leave residue.

2. Allow surface to completely dry before proceeding to next step.

3. Taking care not to touch adhesive, peel off protective backing.

4. Press your thumb firmly against the mount for several seconds.

5. Wait several hours to allow the adhesive to fully bond with the surface.

Resources

| FlexTack Brochure

View PDF |